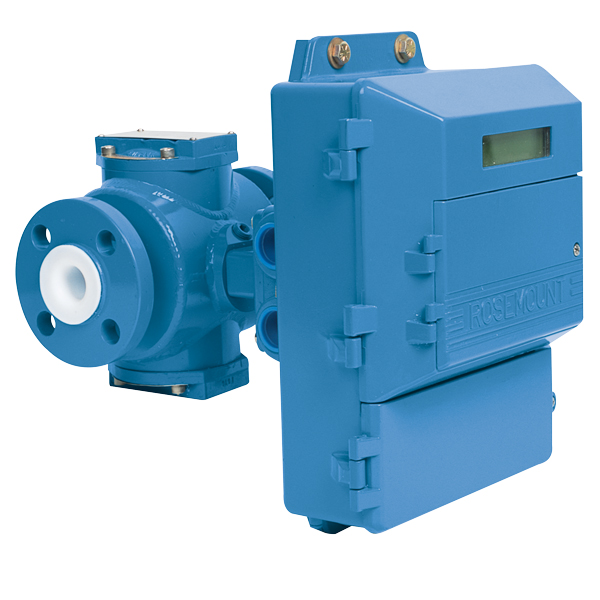

Features: digitalYEWFLO Vortex Flowmeter

| - | New functions with Spectral Signal Processing (SSP) technology |

| SSP analyses the fluid conditions inside the digitalYEWFLO vortex flowmeter and uses the data to automatically select the optimum adjustment for the application, providing features never seen before in a vortex flowmeter. SSP accurately senses vortices in the low flow range, providing outstanding flow stability. | |

| - | Advanced self-diagnostics |

| Application conditions such as high pipeline vibration and abnormal flow are predicted and indicated. | |

| - | High accuracy |

| ±0.75% of reading (liquid) ±1.0% of reading (gas, steam) | |

| - | Wide process temperature range |

| High temperature version up to 450 deg C Cryogenic version minimum -196 deg C | |

| - | Simple parameter settings |

| Frequently-used selections grouped together in a quick-access format decrease commissioning time | |

| - | Clear, concise indicator |

| Convenient display of the simultaneous and total flow rates together with the process diagnosis | |

| - | Dual output for analog/pulse |

| Simultaneous output for flow rate and pulse | |

| - | Alarm output |

| An alarm signal is output when an alarm occurs. | |

| - | BRAIN/HART communication and key switches for human-machine interface |

| - | NACE compliant |

| - | NAMUR 43 compliant |

| - | Remote cable length up to 30m |

Specifications: digitalYEWFLO Vortex Flowmeters

| Standard Type | Reduced Bore Type | Multi-Variable Type | ||

| Model | Model DY Vortex Flowmeter (Integral Type, Remote Type) Model DYA Vortex Flow Converter (Remote Type) (Option for High Process Temperature Version: /HT, Option for Cryogenic Version: /LT) | Option: /R1, /R2 1 size down: /R1 2 size down: /R2 (Option for High Process Temperature Version: /HT) | Option: /MV | |

| Fluid to be Measured | Liquid, Gas, Steam (Avoid Multiphase Flow and Sticky Fluids) | |||

| Nominal Size | Wafer | 15 to 100 mm | N/A | 25 to 100 mm |

| Flange | 15 to 400 mm | R1: 25 to 200 mm (Detector: 15 to 150 mm) R2: 40 to 200 mm (Detector: 15 to 100 mm) | 25 to 200 mm (Special: 250 to 300 mm) | |

| Accuracy | Liquid | ±0.75% of Reading (Depends on Reynolds number) | ±1.0% of Reading (Depends on Reynolds number) | ±0.75% of Reading (Depends on Reynolds number) |

| Gas Steam | ±1.0% of Reading (Depends on flow velocity) | |||

| Output Signal | Dual Output (Both analog and pulse output available) Communication: HART 5/HART 7, BRAIN, FOUNDATION™ fieldbus | |||

| Process Temperature | -29 to 250 deg C -29 to 450 deg C (/HT) -196 to 100 deg C (/LT) | -29 to 250 deg C -29 to 450 deg C (/HT) | -29 to 250 deg C -29 to 400 deg C (/HT) | |

| Process Pressure | -0.1MPa (-1kg/cm2) to flange rating | |||

| Ambient Temperature | -29 to 85 deg C (Depends on model type) | |||

| Ambient Humidity | 5 to 100% RH (No Condensation) | |||

| Mounting | Flange or Wafer Type JIS 10/20/40K ANSI 150/300/600/900 (Special: 1500) DIN PN 10/16/25/40/ 60/100/160 | Flange Type only JIS 10/20K ANSI 150/300 | Flange or Wafer Type JIS 10/20/40K ANSI 150/300/600/ 900 DIN PN 10/16/25/40 | |

| Electrical Connection | JIS G1/2 Female, ANSI 1/2NPT Female, ISO M20×1.5 Female | |||

| Explosion Protected Type | TIIS Ex d, FM Ex d/Ex ia, ATEX Ex d/Ex ia, CSA Ex d/Ex ia, IECEx Ex d, SAA Ex ia | |||

| Material | Body: Stainless steel(Special: Hastelloy, Carbon steel) Shedder Bar: Duplex stainless steel(Option: Stainless steel, Hastelloy) Gasket: Stainless steel with Teflon coating (/HT: with Silver plating) Converter housing, case and cover: Aluminum alloy(Option: Stainless steel) | |||

To start your quick quote, please fill out the below form and an China Industry Automation representative will contact you within an hour.

Receive a reply within 30 minutes, when you submit a Quick Quote Request Monday-Friday between 8:30 a.m. and 6:00 p.m. CST. Requests received outside of these hours will receive a reply the next business day.