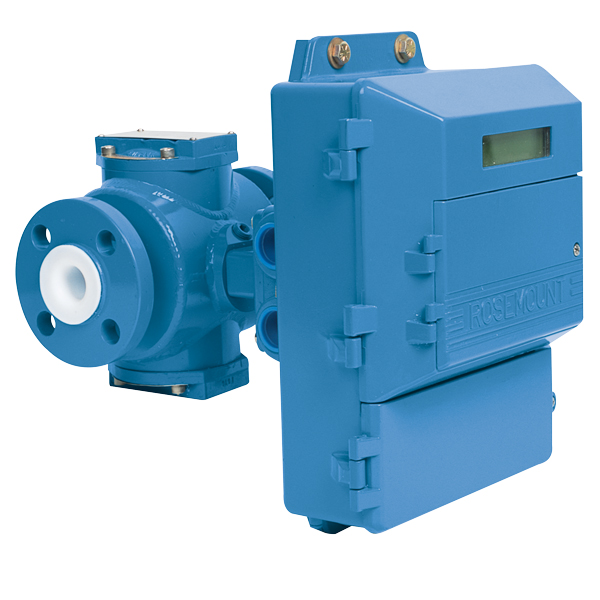

Features: High Process Temperature Version / Cryogenic Version

| - | New functions with Spectral Signal Processing (SSP) technology |

| SSP analyses the fluid conditions inside the digitalYEWFLO vortex flowmeter and uses the data to automatically select the optimum adjustment for the application, providing features never seen before in a vortex flowmeter. SSP accurately senses vortices in the low flow range, providing outstanding flow stability. | |

| - | Advanced self-diagnostics |

| Application conditions such as high pipeline vibration and abnormal flow are predicted and indicated. | |

| - | High accuracy |

| ±0.75% of reading (liquid) ±1.0% of reading (gas, steam) | |

| - | Wide process temperature range |

| High temperature version up to 450 deg C Cryogenic version minimum -196 deg C | |

| - | Simple parameter settings |

| Frequently-used selections grouped together in a quick-access format decrease commissioning time | |

| - | Clear, concise indicator |

| Convenient display of the simultaneous and total flow rates together with the process diagnosis | |

| - | Dual output for analog/pulse |

| Simultaneous output for flow rate and pulse | |

| - | Alarm output |

| An alarm signal is output when an alarm occurs. | |

| - | BRAIN/HART communication and key switches for human-machine interface |

| - | NACE compliant |

| - | NAMUR 43 compliant |

| - | Remote cable length up to 30m |

Specifications:High Process Temp. Version / Cryogenic Version

| Standard | Reduced Bore | |||||||||||||

| Model & code | DY Vortex Flowmeter | Option code:/R1,/R2 | ||||||||||||

| Fluid to be measured | Liquid, gas, steam (avoid multiphase flow and sticky fluids) | |||||||||||||

| Nominal size | 15mm ∼ 300mm (400mm:special) | 25mm ∼ 200mm | ||||||||||||

| Accuracy |

|

| ||||||||||||

| Gas, steam: ±1.0% of reading (flow velocity less than 35m/s) Gas, steam: ±1.5% of reading (flow velocity 35m/s~80m/s) | ||||||||||||||

| Output signal | Simultaneous output(both analog and transistor contact output available) | |||||||||||||

| Process temperature range | -29 deg C ∼ 260 deg C(standard) -196 deg C ∼ 100 deg C(option: cryogenic version) -29 deg C ∼ 450 deg C(option: high process temperature version) | |||||||||||||

| Process pressure limit | -0.1MPa (-1kg/cm2) to flange rating | |||||||||||||

| Ambient temperature | -29 to 85 deg C (Integral type / No indicator) -29 to 80 deg C (Integral type / with indicator) -29 to 85 deg C (Remote type detector) -40 to 85 deg C (Remote type converter / No indicator) -30 to 80 deg C (Remote type converter / with indicator) | |||||||||||||

| Ambient humidity | 5~100%RH( Non-condensing) | |||||||||||||

| Mounting | Integral type and Remote type detector: Flange mounting or wafer mounting Remote type converter: 2 inch pipe mounting JIS10/20/40、ANSI150/300/600/900, JPI150/300/600,DIN PN10/16/25/40 | |||||||||||||

| Electrical connection | JIS G1/2 female, ANSI 1/2NPT female, ISO M20×1.5 female | |||||||||||||

| Electrical classification | JIS flameproof, FM explosion proof/intrinsically safe ATEX (CENELEC flameproof/intrinsically safe/IEC type n) CSA explosion proof/intrinsically safe : Dual Seal SAA flame proof/intrinsically safe | |||||||||||||

| Material | Body: SCS14A cast stainless steel (equivalent to SUS316,CF8M) Shedder bar: duplex stainless steel (option:anti-corrosion version) Gasket: SUS316 stainless steel with polytetrafluoroethylene (Teflon) coating Converter housing and case cover: aluminum alloy or ASTM CF8M (equiv. JIS SCS14A) (Option: /E1) | |||||||||||||

| Applicable Standard | *EMC Conformity Standards: EN61326-1 Class A, Table 2 (For use in industrial locations), EN61326-2-3 EN55011 Class A Group 1 *Pressure Equipment Directive: Notified Body Identification Number 0038 Module H | |||||||||||||

To start your quick quote, please fill out the below form and an China Industry Automation representative will contact you within an hour.

Receive a reply within 30 minutes, when you submit a Quick Quote Request Monday-Friday between 8:30 a.m. and 6:00 p.m. CST. Requests received outside of these hours will receive a reply the next business day.