Promag P 100 isdedicated for chemical and process applications with corrosive liquids and highmedium temperatures. Combined with the smallest transmitter housing availabletoday it delivers full performance on the smallest footprint. Designed forapplications where space is a premium, it will be the preferred choice forsystem integrators, skid builders and equipment manufacturers.

Benefits

Versatile applications – wide variety ofwetted materials

Energy-saving flow measurement – nopressure loss due to cross-section constriction

Space-saving transmitter – fullfunctionality on the smallest footprint

Time-saving local operation withoutadditional software and hardware – integrated web server

Integrated verification – HeartbeatTechnology™

application

The measuring principle is virtuallyindependent of pressure, density, temperature and viscosity

Dedicated for chemical and processapplications with corrosive liquids and high medium temperatures.

Device properties

Nominal diameter: max. DN 600 (24")

All common Ex approvals

Liner made of PTFE or PFA

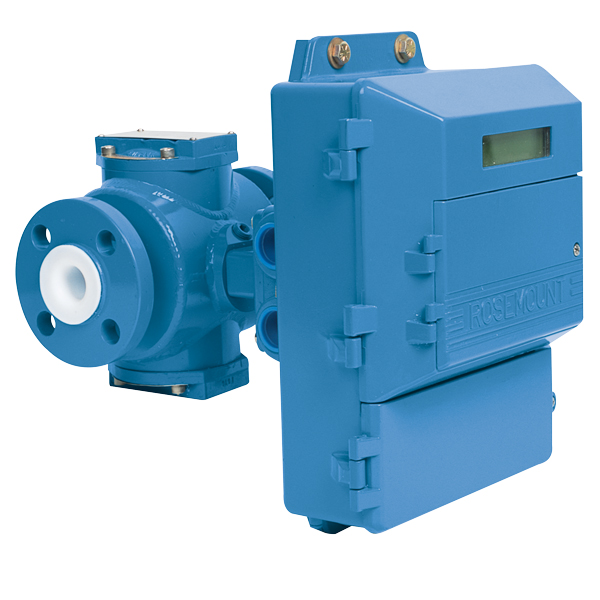

Robust, ultra-compact transmitter housing

Local display available

specifications

| Measuring Principle | Electromagnetic |

| Product headline | The flowmeter for highest medium temperatures with an ultracompact transmitter. Dedicated for chemical and process applications with corrosive liquids and high medium temperatures. |

| Sensor features | Versatile applications – wide variety of wetted materials. Energy‐saving flow measurement – no pressure loss due to cross‐section constriction. Maintenance‐free – no moving parts. Nominal diameter: max. DN 600 (24"). All common Ex approvals. |

| Transmitter features | Space‐saving transmitter – full functionality on the smallest footprint. Time‐saving local operation without additional software and hardware – integrated web server. Integrated verification – Heartbeat Technology™. Robust, ultra‐compact transmitter housing. |

| Nominal diameter range | DN 15 to 600 (½ to 24") |

| Wetted materials | Liner: PFA, PTFE |

| Measured variables | Volume flow, conductivity, mass flow, corrected volume flow, corrected conductivity |

| Max. measured error | Volume flow (standard): ±0.5 % o.r.± 1 mm/s (0.04 in/s) |

| Measuring range | 4 dm³/min to 9600 m³/h (1 to 44 000 gal/min) |

| Max. process pressure | PN 40, Class 300, 20K |

| Medium temperature range | Liner material PFA: –20 to +150 °C (–4 to +302 °F) |

| Ambient temperature range | Flange material carbon steel: –10 to +60 °C (+14 to +140 °F) |

| Sensor housing material | DN 15 to 300 (½ to 12"): AlSi10Mg, coated |

| Transmitter housing material | AlSi10Mg, coated |

| Degree of protection | IP66/67, type 4X enclosure |

| Display/Operation | 4‐line backlit display available (no local operation) |

| Outputs | 4‐20 mA HART (active) |

| Inputs | None |

| Digital communication | HART, PROFIBUS DP, Modbus RS485, EtherNet/IP |

| Power supply | DC 20 to 30 V |

| Hazardous area approvals | ATEX, IECEx, cCSAus, Inmetro |

| Other approvals and certificates | 3.1 material, calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025), NAMUR |

To start your quick quote, please fill out the below form and an China Industry Automation representative will contact you within an hour.

Receive a reply within 30 minutes, when you submit a Quick Quote Request Monday-Friday between 8:30 a.m. and 6:00 p.m. CST. Requests received outside of these hours will receive a reply the next business day.