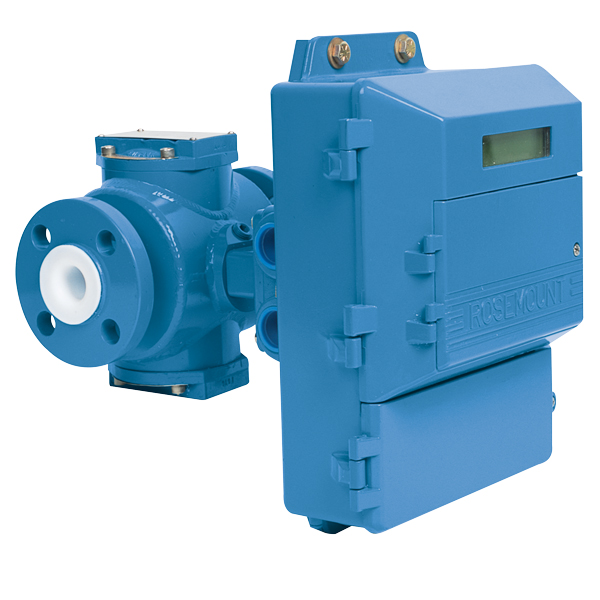

Promag L is theversatile standard sensor designed for the water industry with a lap-jointflange concept for flexible installation independent of the orientation of thepipe flange pitch diameter. Combined with Proline 400, the transmitter foroptimized measurement of water and wastewater, Promag L 400 will be thepreferred solution for all standard applications in this industry. Promag L 400also offers an integrated web server. Integrated verification with HeartbeatTechnology.

Benefits

Reducedinstallation costs – flexible mounting by one-of-a-kind lap-joint flangeconcept (DN < 350/14")

Energy-savingflow measurement – no pressure loss due to cross-section constriction

Maintenance-free– no moving parts

Safe operation –no need to open the device due to display with touch control, backgroundlighting

Time-savinglocal operation without additional software and hardware – integrated webserver

Integratedverification – Heartbeat Technology™

application

The measuringprinciple is virtually independent of pressure, density, temperature andviscosity

Fully suitablefor standard applications in the water and wastewater industry.

Deviceproperties

Up to 30% lesssensor weight

Nominaldiameter: DN 25 to 2400 (1 to 90")

Maximum reducedinstallation length to DVGW/ISO

Transmitterhousing made of durable polycarbonate or aluminium

Same housingconcept for compact/remote version

Integrated datalogger: measured values monitoring

specifications

| Measuring Principle | Electromagnetic |

| Product headline | The flowmeter with integrated web server and a weight‐optimized sensor. Fully suitable for standard applications in the water and wastewater industry. |

| Sensor features | Reduced installation costs – flexible mounting by one‐of‐a‐kind lap-joint flange concept (DN < 350/14"). Energy‐saving flow measurement – no pressure loss due to cross‐section constriction. Maintenance‐free – no moving parts. Up to 30 % less sensor weight. Nominal diameter: DN 25 to 2400 (2 to 90"). |

| Transmitter features | Safe operation – no need to open the device due to display with touch control, background lighting. Time‐saving local operation without additional software and hardware – integrated web server. Integrated verification – Heartbeat Technology™. Transmitter housing made of durable polycarbonate or aluminium. Same housing concept for compact/remote version. |

| Nominal diameter range | Lap joint flange, lap joint flange, stamped plate: DN 25 to 300 (1 to 12") |

| Wetted materials | Liner: PTFE; Polyurethane; Hard rubber |

| Measured variables | Volume flow, conductivity, mass flow |

| Max. measured error | Volume flow (standard): ±0.5 % o.r. ± 1 mm/s (0.04 in/s) |

| Measuring range | 9 dm³/min to 162 000 m³/h (2.5 gal/min to 1030 Mgal/d) |

| Max. process pressure | PN 16, Class 150 |

| Medium temperature range | Liner material hard rubber: 0 to +80 °C (+32 to +176 °F) |

| Ambient temperature range | Flange material carbon steel: –10 to +60 °C (+14 to +140 °F) |

| Sensor housing material | DN 25 to 300 (1 to 12"): AlSi10Mg, coated |

| Transmitter housing material | Polycarbonat; AlSi10Mg, coated |

| Degree of protection | Compact version: IP66/67, type 4X enclosure |

| Display/Operation | 4‐line backlit display with touch control (operation from outside) |

| Outputs | 3 ouputs: |

| Inputs | Status input |

| Digital communication | HART, PROFIBUS DP, EtherNet/IP, Modbus RS485 |

| Power supply | AC 100 to 240 V / AC/DC 24 V |

| Hazardous area approvals | cCSAus |

| Other approvals and certificates | Calibration performed on accredited calibration facilities (acc. to ISO/IEC 17025), NAMUR Drinking water approval: ACS, KTW/W270, NSF 61, WRAS BS 6920 |

To start your quick quote, please fill out the below form and an China Industry Automation representative will contact you within an hour.

Receive a reply within 30 minutes, when you submit a Quick Quote Request Monday-Friday between 8:30 a.m. and 6:00 p.m. CST. Requests received outside of these hours will receive a reply the next business day.